|

Rule 3.9 - Front Body

Mounting Install

Below is my install to meet the new

front body mounting requirements of rule 3.9. In no way is this the only

way to do it but should give you a guide to the process. Once again I

was lucky in that the front body of my car was already off. This made my

install pretty easy and straight forward. Having completed it, I feel

that it could be done with the body on but with considerably more

difficulty in locating the holes.

3.9 Front Body Mounting

To help

prevent intrusion of the body into the drivers compartment, the cowl

area of the body (the area above and forward of the dash) must be

through bolted to the two ¾ steel tubes on the chassis that extend

forward from the dash hoop into the engine bay. Two 5/16 inch diameter

bolts must be used on each side. Large washers should be used on both

the body and chassis sides to prevent bolt heads from being pulled

through.

Since these

cars are hand made and owner built, the measurements I give below are

only presented to describe the process. Your measurements will more than

likely be different.

I started on the driver side

because of the wind screen. I knew I would have to work around it.

NOTE: You may have to remove and relocate your wind screen. First

you need to figure out where below the body is the ¾ tube. Use whatever

method works for you. The goal at this point was to get a rough idea

where the bolts through the body would hit the ¾ tube. What I found

was that if I put the first hole close to the dash hoop, I could get the

second hole about 1.5 to the front and still clear the windscreen with

room for an oversized washer.

|

|

|

|

Driver Side-Frame holes

Bolts are inserted just to show hole location. |

Passenger Side

Bolts are inserted just to show hole location. |

Since there was nothing on the passenger side to work around, I simply

dilled to holes in approximately the same position as the d-side. At

this point, the body was put in place and aligned with the normal body

mounts. Note: Put the bolts in as to assure the body is aligned as it

will be when you bolt everything at the end. With the body in place,

stick your drill bit up through the holes in the ¾ tube from the bottom

and twist it. This will mark your hole on the body. Next the body was

removed and the holes were drilled.

With the holes drilled, put the body back on and check the holes you

just drilled. I did this with a 4 5/16 bolt. What I found is the holes

in the body were drilled at a slightly different angle. To bring

everything in alignment, run your drill bit down through the body holes

and into the frame holes. This will align the holes.

|

|

| Driver Side |

Passenger Side |

By now you may have noticed that you have drilled through a part of the

body that is not horizontal and that the bolt heads will not sit flush

to the body. Also, there is a considerable gap between the underside of

the body and the ¾ tubes. In order for this mounting to be strong and

do what is intended, you will need to fabricate some spacers and decide

what you are going to use on the top of the body.

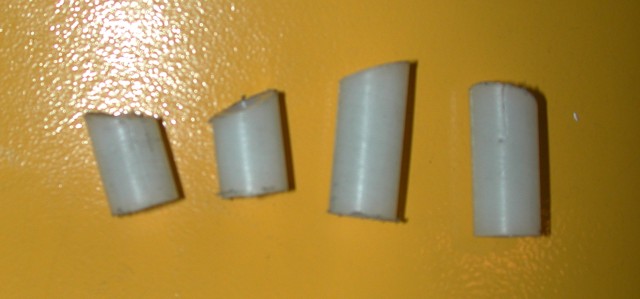

In my install, I

determined the d-side mounts sat on a 12.5 degree slope and the p-side

was 18 degree. I measured the gap between the body and tubes. Note:

They were different on both sides, 1.125 on d-side and 0.875 p-side.

I cut the above angles into some 9/16 nylon rod that I cut to length

and drilled.

|

| Nylon spacers to go between

body and 3/4" tube. Angle cut to match body. |

As for washers on top of the body,

I looked for a solution but could not find any beveled washers that

would work in this situation. So it was down into the metal shop to

fabricate a solution. Below is my solution. The aluminum pieces are

approximately 1x2.5. I milled the body angle into them and they fit

perfect.

|

|

Fabricated Washers

Cut to

angle of the body. |

|

|

| Thin Side |

Thick Side |

Put it all together and you have a

very strong mount with the load on the bolts distributed properly. You

might get away with using flat washers but my fear was that the body

might tear due to an uneven load under normal conditions.

|

|

|

Driver

side installed

Bolts

only for show. |

Passenger side installed

Bolts

only for show. |

The bolts you see in the above pictures are just

there for demonstration purposes. I plan to use stainless steel button

head cap screws, like the FFR provided body bolts, in the final

installation. For my installation, I ordered 3 bolts for both sides and

Nyloc nuts.

I wont say this was an easy modification but it is

certainly necessary. Watching a video of my head on collision last year,

I saw just how far the cowl lip of the body intruded into the cockpit. I

was lucky it was on the p-side. Had it been the drivers side, Im sure

it would have hurt my hands.

--Brian Sanders |